|

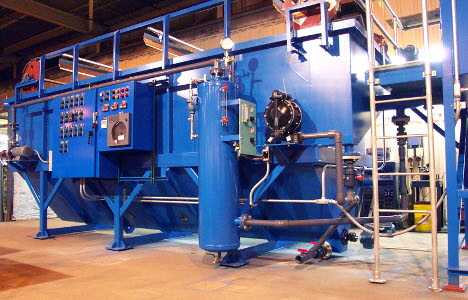

Tenco Hydro Clari-Float provides high performance by the use of proprietary design features to maximize DAF performance. These include a proprietary inlet chamber and recycle pressurization system. Tenco Hydro Clari-Float provides high performance by the use of proprietary design features to maximize DAF performance. These include a proprietary inlet chamber and recycle pressurization system.

The inlet chamber dissipates energy and turbulence from the mixing of feed and depressurizing flows. It is then transformed to an evenly distributed laminar flow as it enters the DAF cell. Additionally, any excess (undissolved) air is captured and vented outside of the DAF cell, thus preventing air turbulence and disruption of the floated sludge at the surface. This results in optimum use of the DAF cell flotation area.

Optimum DAF performance also requires consideration of influent characteristics to determine the applicable design parameters such as hydraulic and solids loading rates and air to solids ratio. Air is delivered by the use of pressurized recycle flow. Tenco's proprietary recirculation system has been proven, by rigorous full scale testing, to dissolve air in water in excess of 87% saturation efficiency. This high efficiency minimizes the energy used to deliver the air necessary for solids flotation.

Clari-Float DAF systems have been supplied in circular, rectangular and rectangular high rate configurations. Materials of construction have been carbon steel, stainless steel or concrete.

Tenco Hydro continues to develop, refine and improve designs for DAF applications. Designs are focused on high performance, reliable operation and long service life. Clari-Float DAF units perform at levels few achieve. With hundreds of units installed, Tenco Hydro remains a leader in DAF technology.

|