Level Solutions

Our Approach to Specifying Level Instrumentation:

Level is an art and a science! We'll work with you to find the best solution.

With decades of expertise in specifying and integrating level instrumentation, we have consulted on instrumentation not only for our own advanced wastewater treatment equipment, but also for various applications across a wide range of industries!

Our deep understanding of process control and measurement allows us to recommend and implement the most reliable and accurate level sensing solutions, tailored to the unique demands of each application.

Our Preferred Vendors

Technologies We Work With:

- Radar – Guided Wave & Free Space

- DP Level

- Hydrostatic

- Point Level – Gap, tuning fork, frequency sweep

- Capacitance

- Sonar

- Magnetostrictive

- Gamma

- Magnetic Level Indicator (MLI)

- And more!

Application Highlight

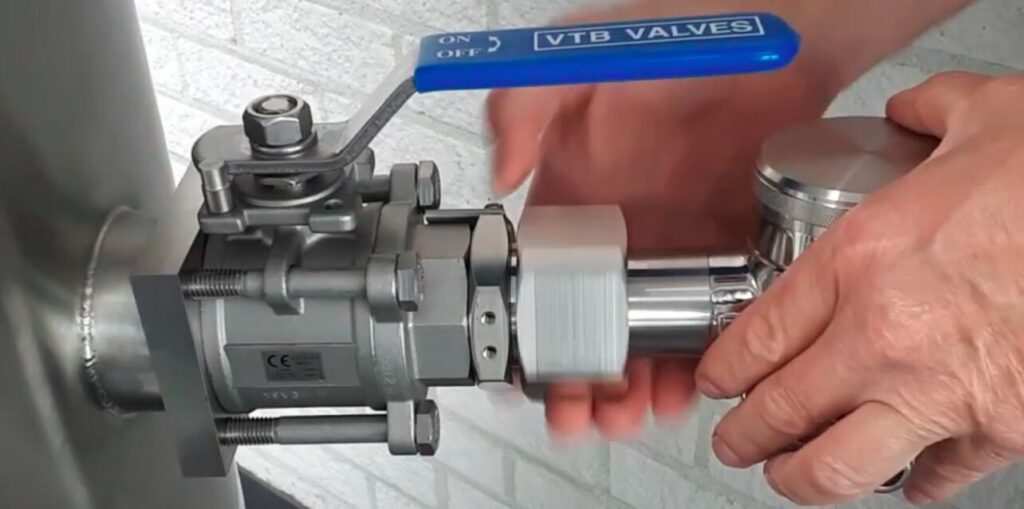

Klay 2000-Valve

Downtime: Optional

How It Works

Step 1:

Unscrew 1st Fitting

Step 2:

Partially Remove Transmitter. Close The Ball Valve

Step 3:

Unscrew 2nd Fitting

Step 4:

Remove & Replace Diaphragm – During Operation!

All Stainless Steel Housing

Response Time: 1-20 ms

Active Temperature Compensation

Ceramic & Steel Sensor Technology

Both Piezo and Capacative Sensors

-

6, 26, 80 GHz Radar

-

Guided Wave Radar

-

Cable, Rod & much more!

-

-

Free Space Radar

Self-Cleaning Available

-

2-Wire Ultrasonic

Media Independent Measuring Principle

LED Fill Level Indicator

FDA, EHEDG, 3A Conformity

All Stainless Housing or Construction

Any Process Connection, Insertion Length, Sensitivity

Resistant to all common CIP cleaning media and SIP-capable

Flush Mounted Ceramic Sensor

Active Temperature Compensation

Easy adjustable using 3 push buttons, without test pressure

Strong flush diaphragm

Active temperature compensation

Tank linearization

Non-clogging sensor cage