Wastewater Treatment, Perfected

Automatic Polymer Feeding - Precision Dosing for Maximum Efficiency

Neat Polymer Feeder

Auto Polymer Feeder Mixer

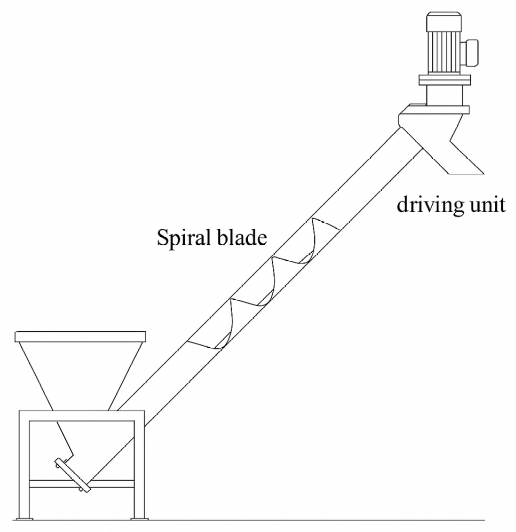

Dry Powder Polymer Conveyance

Precise Dosing for Consistent Polymer Activation

Reduced Polymer Waste and Operational Costs

Reliable high-quality polymer activation

Save up to 30% on polymer waste!

Fully automatic operation:

No manual handling

Optional:

integral pH feedback loop

Continuous, dust-free transfer to mixing systems

Precise volumetric control

Minimize product loss, Maximize polymer use efficiency!

Closed transfer system

Why Automate Polymer Feeding?

An automatic polymer feeder optimizes the coagulation and flocculation process, ensuring consistent chemical dosing, improving DAF performance, and reducing operating costs.

✅ Lower Polymer Consumption & Chemical Costs – Precise dosing prevents overuse of polymers, reducing waste and expenses.

✅ Better Effluent Quality – Optimized polymer dosing results in lower TSS and turbidity, improving water clarity and compliance.

✅ Automated Dosing for Process Stability – Adjusts in real-time to fluctuations in flow rate and solids loading, ensuring consistent separation performance.

✅ Reduced Labor Requirements – Eliminates manual dosing adjustments, freeing up staff for other critical tasks.

✅ Reliable & Maintenance-Free Operation – Designed for continuous performance, minimizing downtime and maintenance needs.

Seamless Integration

🔗 Works with Existing Systems – Easily integrates with DAF units, chemical tanks, and SCADA systems.

⚡ Energy-Efficient Design – Optimizes dosing without excessive power consumption.

By implementing an automatic polymer feeder, DAF systems achieve higher efficiency, lower costs, and improved effluent quality—all with hands-free operation! 🚀

Turbidity Sensors - Real-Time Effluent Monitoring

Optimal Turbidity: <10 NTU (for regulatory compliance)

Turbidity sensors measure the amount of suspended solids in water by detecting how much light is scattered by particles. This provides a direct indication of DAF separation efficiency.

✅ Ensures Compliance – Monitors turbidity in real-time to maintain discharge limits (<10 NTU for many industries) and prevent violations.

✅ Prevents Process Upsets – Detects sudden spikes in turbidity, indicating issues like poor coagulation, air saturation problems, or excessive scum buildup.

✅ Automated Process Adjustments – Integrates with chemical dosing and skimmer controls to optimize separation when turbidity levels fluctuate.

✅ Reduces Chemical Waste – Avoids overdosing of coagulants and polymers by ensuring just the right amount of treatment is applied.

Optical Sensors - Confirm Your Solids and Water Clarity

Coagulant dosing adjustment at TSS > 50 mg/L

Optical Sensors use light-based detection to monitor bubble formation, sludge interface levels, and solids concentration.

✅ Optimized Air-to-Solids Ratio – Ensures proper microbubble distribution by monitoring air injection and dissolved air concentration.

✅ Accurate Sludge Blanket Measurement – Detects sludge accumulation and interface levels, preventing excessive sludge carryover or under-removal.

✅ Prevents Effluent Contamination – Identifies floating solids or scum overflow, allowing for quick corrective action.

✅ Improves Skimmer and Pump Efficiency – Provides real-time feedback to adjust skimmer speed, sludge pump activation, or chemical dosing for optimal performance.