Custom Piping Assemblies & Industrial Manifolds

From Concept to Reality:

- Idea

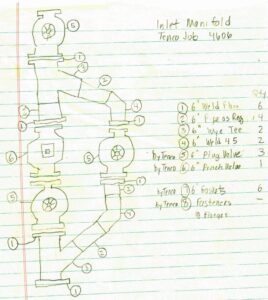

- Rough Sketch

- CAD

- Fabrication

1. Custom Piping Assemblies

We design and fabricate piping systems that are engineered for efficiency, safety, and long-term reliability

✅ Material Selection – Stainless steel, carbon steel, PVC, HDPE, PTFE-lined piping, and specialty alloys.

✅ Custom Configurations – Straight-run, looped, skid-mounted, and multi-branch assemblies.

✅ Precision Fabrication – Pre-engineered to minimize installation time and ensure leak-free performance.

2. Industrial Manifold Design

Our custom manifolds ensure controlled fluid distribution and system optimization

✅ Multi-Port Flow Management – Direct liquids, gases, and steam to multiple process points.

✅ Integrated Valve Systems – Ball, gate, check, pressure-relief, and solenoid valves for precise flow control.

✅ Customizable Connection Types – Flanged, threaded, welded, sanitary clamp, and quick-connect fittings.

3. Compliance & Industry Standards

Every system is built to meet or exceed industry safety and performance requirements

✅ ASME B31.1 & B31.3 – Piping code compliance for power and process industries.

✅ ANSI & ASTM Standards – Ensuring material strength, pressure ratings, and corrosion resistance.

✅ FDA & 3A Sanitary Design – For food, beverage, and pharmaceutical applications.

✅ UL, ATEX, & IECEx – Certification for hazardous locations and explosion-proof piping systems.

4. Full-Service Engineering & Support

We provide comprehensive design assistance and project support

✅ Custom CAD Modeling & Flow Simulation – Optimized layouts for performance and efficiency.

✅ Selection Tools & Part Numbering System – Simplifies specification and ordering.

✅ Pre-Assembled & Modular Solutions – Reducing installation time and labor costs.