Conveyance Configurations

From precise micro-dosing to high-capacity transfer, we offer auger systems ranging from 1″ to 10″ diameters to suit every application. Whether you need a budget-friendly solution to move just 2 cups of coagulant, or a high-speed system capable of delivering 350 lbs of powder in under 3 minutes, we’ve got the right configuration to match your flow rate, footprint, and budget.

Need Automation? Let us design you a hands-free system!

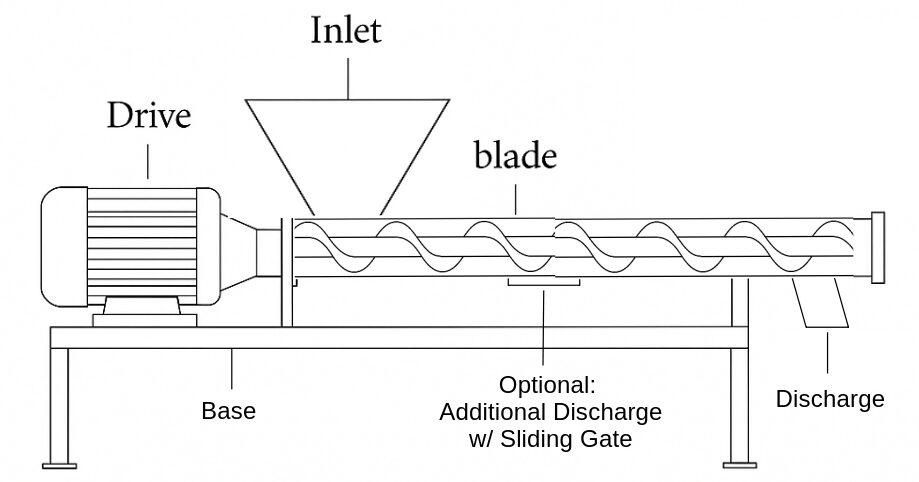

Horizontal Conveyance

Best For:

Consistent feed rate control

Advantages:

Most energy-efficient configuration

Simple to install and maintain

Allows multiple inlets/outlets

Can integrate with hoppers and bins easily

Use Cases:

Transferring dry solids between two points at the same elevation

Dosing systems (due to good metering control)

Vertical Conveyance

Best For:

Lifting material straight up in tight footprints

Advantages:

Maximizes floor space

Ideal for transferring materials to elevated bins, silos, or tanks

Choke-fed = consistent vertical transport

Challenges:

Requires more power

Needs controlled feed to prevent fallback

- Recommended control: continuous feed, choke-fed, VFD, check valve.

Use Cases:

Feeding into reactors, mixers, or silos from a hopper

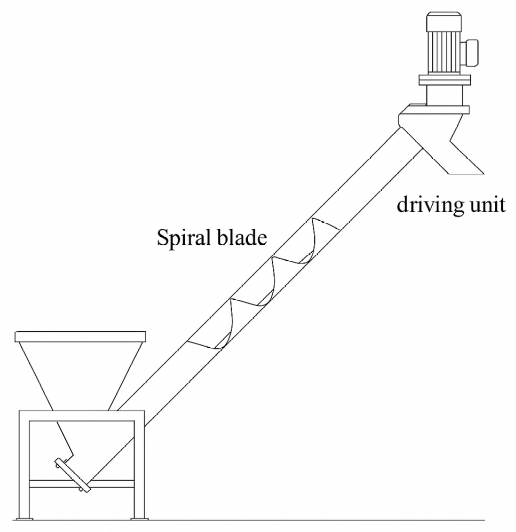

Angled (Incline) Conveyance

Best For:

Combining lift and length in one conveyor

Advantages:

Compromise between horizontal and vertical

Can be gravity-fed or choke-fed depending on angle

Considerations:

Efficiency drops as angle increases (ideal: <45°)

Use Cases:

Feeding mixers, dryers, or intermediate tanks from floor-level bins

Mobile conveyor systems (like bag unloading or batching setups)

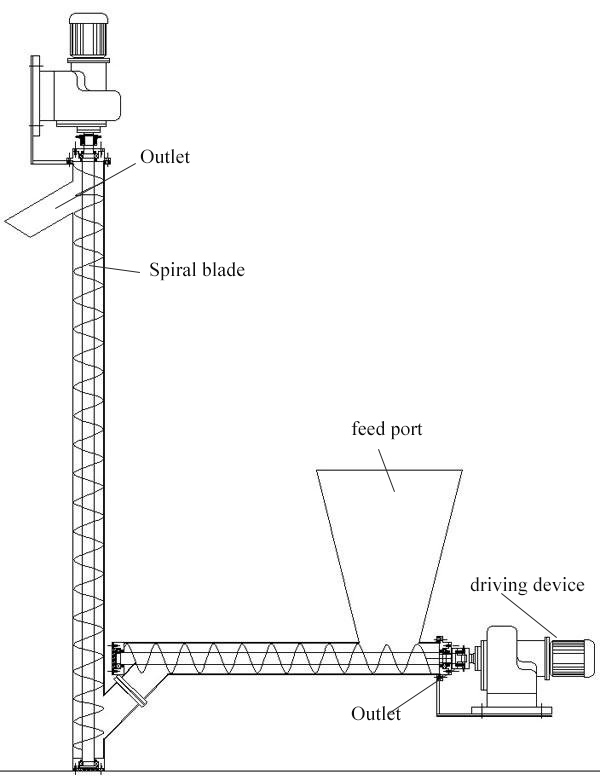

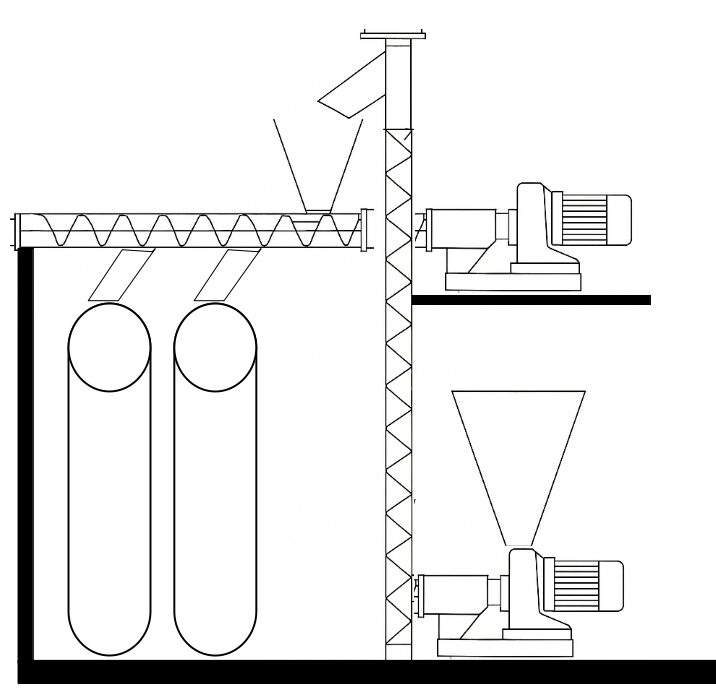

Dual-Plane Conveyance

Typically consists of:

Horizontal section → for collection, metering, or transfer

Vertical section → for elevation to discharge point

Best For:

Applications with tight floor space and high discharge elevation

Integrating collection, metering, and elevation in a single system footprint

Advantages:

Compact footprint

Choke-fed vertical section – consistent flow and minimizes fallback

Versatile layout adaptable to a wide range of equipment and plant configurations

Recommended Control Strategy:

Install a VFD (Variable Frequency Drive) for smooth start/stop and speed control

Include a check valve or slide gate to prevent backflow when system is idle

Design for continuous or semi-continuous operation to avoid surging and air gaps

Use Cases:

Transferring powder or granules from a ground-level hopper to an overhead silo, batch mixers or reactors

Compact floor footprint