Metal finishing plants face some of the most demanding wastewater treatment challenges in industry. Between heavy metals, oils, surfactants, and shifting pH, Dissolved Air Flotation (DAF) is often the go-to technology to polish wastewater before discharge or reuse.

But not all DAF systems are created equal — and the pressurization method used to generate dissolved air can have a major impact on efficiency, reliability, and treatment performance.

In this post, we’ll compare the top DAF pressurization options and recommend the best fit for metal finishing wastewater.

⚙️ Option 1: Krofta-Style Air Dissolving Tube

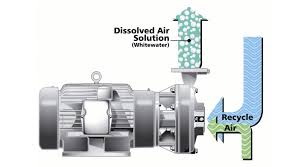

This method uses a long, shear-inducing tube (commonly called a Krofta tube) where air is introduced and partially dissolved into a high-pressure stream via a centrifugal pump.

Pros:

- Simple and compact

- Low equipment cost

- No need for an air compressor

Cons:

- Lower saturation efficiency

- Poor performance with variable loads or oils

- Limited ability to control bubble size or recycle flow

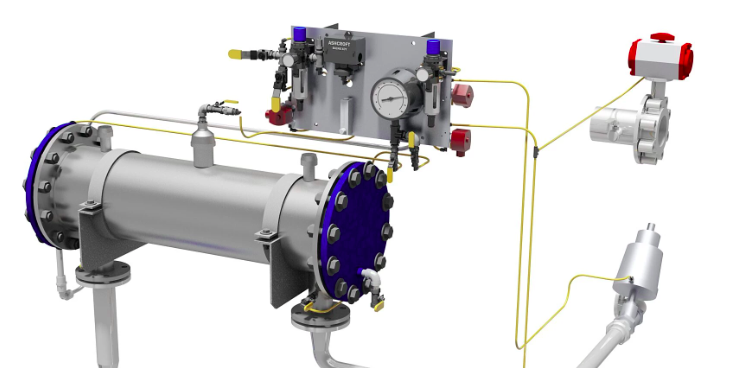

🚀 Option 2: Skid-Mounted Saturation System with Whitewater Recycle

This configuration uses a dedicated recycle pump, inline air injection, and a pressurized saturation tank mounted on a skid. It produces ultra-fine bubbles and maintains a consistent whitewater flow even under variable load conditions.

Pros:

- High bubble saturation efficiency

- Stable performance with pH and flow changes

- Modular skid simplifies installation and servicing

- Easily integrates flow, pressure, or pH sensors for full automation

Cons:

- Higher upfront cost

- Requires more floor space

- May require external air compressor

🌪️ Option 3: Pressurization System Using a Hellbender Pump (or Equivalent)

This option integrates a Hellbender Pump — or similar vortex/recessed impeller pump — into the DAF recycle loop. These pumps are specifically designed for solids-laden, abrasive, or chemically aggressive liquids, making them ideal for harsh metal finishing wastewater

Pros:

- Excellent resistance to clogging from grit or floc

- Handles metal hydroxide sludge and emulsified oils with ease

- Chemical-resistant construction (e.g., Ni-Hard, CD4MCu)

- Compatible with VFDs for precise flow control

Cons:

- Larger footprint than standard centrifugal pumps

- May require more advanced piping support

- Best suited for mid-to-high flow applications with high solids content

🏆 Best Option for Metal Finishing: Skid-Mounted Saturation System with Whitewater Recycle

Metal finishing wastewater is complex — containing oils, metal hydroxides, surfactants, and pH variation. This demands a system that provides:

-

- Reliable fine bubble generation

-

- Stable operation despite load fluctuations

-

- Modular controls for pH/coagulant adjustment

The saturation skid system consistently outperforms simpler designs like air tubes and provides broader configurability than fixed-pump setups. It’s ideal for plants dealing with variable influent quality and seeking high removal efficiency.

🔬 Specific Challenges in Metal Finishing

DAF systems in this sector must manage:

- Emulsified oils and surfactants (harder to float)

- Fine metal hydroxides that settle fast or float poorly

- pH shifts that impact floc formation

- Corrosive environments requiring chemical-resistant materials

That’s why high-performance pressurization skids with materials like 316SS, PVC, or CPVC piping and VFD-controlled recycle pumps are often recommended.

🧪 Bonus Tip: Optimize with pH and Coagulant Control

In metal finishing, coupling a well-designed pressurization system with real-time pH and coagulant control can make a dramatic difference. Ensuring your whitewater has the right chemistry for bubble attachment and floc flotation ensures maximum removal rates—even as wastewater composition varies.

🏁 Bottom Line

For metal finishing plants, the recycle loop whitewater pressurization skid remains the gold standard. It offers:

- ✅ Consistent, fine microbubble generation

- ✅ Robust handling of oily and metallic contaminants

- ✅ Precise process control

- ✅ Modularity and ease of maintenance

While other systems may work in lower-demand applications, metal finishing operations demand a solution built for high solids, variable pH, and consistent performance.

Would you like this adapted into a downloadable brochure or web-friendly blog layout with graphics?